Mineral rubber and metal slurry pump heavy slurry pump

The AM(R) heavy type of Rubber and Metal slurry pump is the heavy duty pump handling tough and abrasive duties major used at mining and mineral departments!

It is the pump transporting Solid-liquid mixture with solid suspending (like ore, sand, gravel, ash and slime etc.) or the abrasive strongly and high concentration slurry.

Pump Specification

The AM(R) heavy type of Rubber and Metal slurry pump the single Stage, cantilever design split case industrial pump. You should know it from the structure, materails and the application the slurry pumps!

It is the transfer pump or process pump in the mining and mieral process. You could also find them used as the dewatering pump as there are always with solids in the waste water of the mining. Normal water pump price is much lower but the water is not satisifed the abrasion conditions at all.

The AM heavy type of Rubber and Metal slurry pump is the only best pump used in mining and mineral departments!

Don’t trust any stainless steel pumps when there are solids in your liquid handling. The stainless steel is only anti acid pump not anti abrasion at all.

In usual, when your mining using cyclone, mill, thickener etc, you should buy the slurry pump as the feed pump or tansfer pump. The price in the slurry pump are very different as the reason of different materials and find the rigth manufacturer is much important than negotiate in the price. Good and reliable Slurry Pump and its parts should work more than 1 years when you work condistion is not very abrasion or wrong operation!

The heavy and robust slurry pump and perfect used perfect impeller structure ensure satisfactory performance with long life and needs minimum maintenance requirements.

The Rubber liner slurry pump expand applications to chemical products handling, several different rubber options are avaiable to meet different application needs, continuous pumping of highly abrasive/dense slurries in processes from cyclone feed to regrind, mill discharge, flotation,mine drainage, dredging of settling lagoons and pumping of drilling mud and tailings in minerals plants plus other industrial applications.

It is the transfer pump or process pump in the mining and mieral process. You could also find them used as the dewatering pump as there are always with solids in the waste water of the mining. Normal water pump price is much lower but the water is not satisifed the abrasion conditions at all.

The AM heavy type of Rubber and Metal slurry pump is the only best pump used in mining and mineral departments!

Don’t trust any stainless steel pumps when there are solids in your liquid handling. The stainless steel is only anti acid pump not anti abrasion at all.

In usual, when your mining using cyclone, mill, thickener etc, you should buy the slurry pump as the feed pump or tansfer pump. The price in the slurry pump are very different as the reason of different materials and find the rigth manufacturer is much important than negotiate in the price. Good and reliable Slurry Pump and its parts should work more than 1 years when you work condistion is not very abrasion or wrong operation!

The heavy and robust slurry pump and perfect used perfect impeller structure ensure satisfactory performance with long life and needs minimum maintenance requirements.

The Rubber liner slurry pump expand applications to chemical products handling, several different rubber options are avaiable to meet different application needs, continuous pumping of highly abrasive/dense slurries in processes from cyclone feed to regrind, mill discharge, flotation,mine drainage, dredging of settling lagoons and pumping of drilling mud and tailings in minerals plants plus other industrial applications.

Mining and Mineral Slurry Pump Application

Slurry Pump FAQ

The most popular quetsions about the slurry pumps:

SlurryPump Structure

AM(R) heavy type of Rubber and Metal slurry pump is the single Stage, cantilever design split case industrial pump /mining and mineral slurry pumps!

The new developement by An Pump Machiery R&D in pump structure and 50 years sustained effort make AM(R) type of horizontal cantilever slurry pump have the min. quatity parts compoistion to lowest your work from the install to daily use.With auto control panel system of us, you could build one completely auto control pump station controlled by your smart phone or computer!

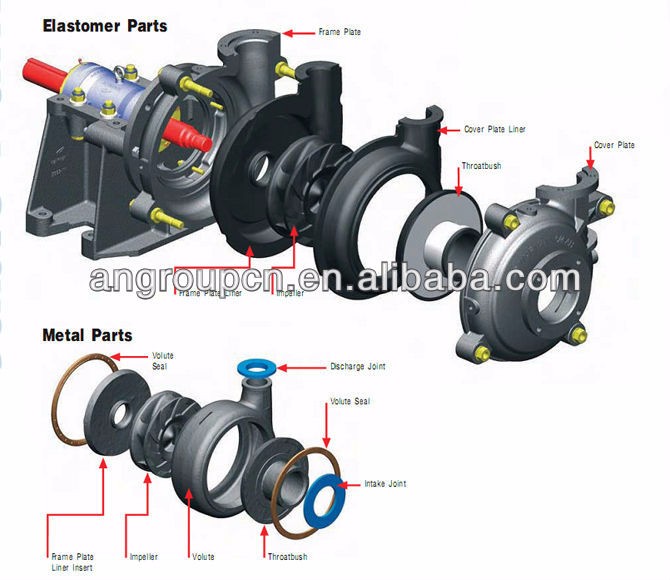

There are two typical pump structurer. One the the rubber lined pump and the other is the metal pump.

Type Metal and Rubber Lined Slurry Pump Structurer

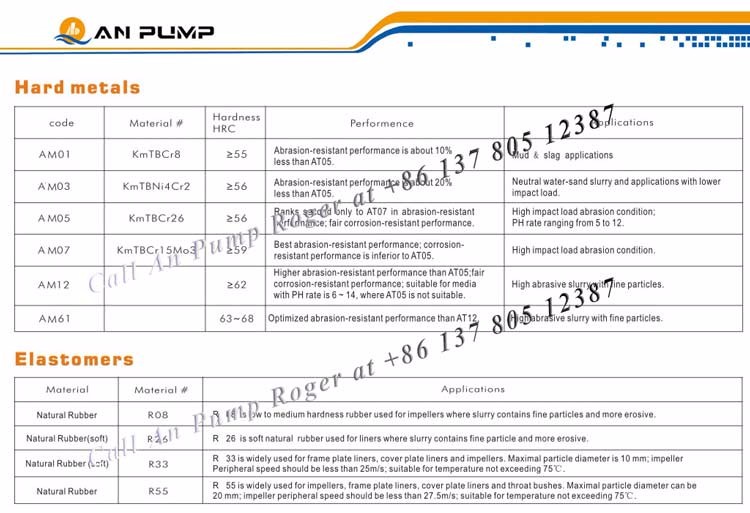

Slurry Pump Material

The AM heavy type of Rubber and Metal slurry pump is the pump anti acid and anti abrasion.

The AM heavy type of Rubber and Metal slurry pump is the heavy duty pump special designed for handling slurry with abrasive and corrosive solids, which maximum weight density of 80% (ash and coal slurry) and 60% (ore and heavy slurry).

The developmemt of the high chrome materials make the AM type of slurry pump become the anti abrasive pump! In some conditions, like some gold mine, the slurries are corrosive when you add chemical in the process and we development the rubber lined AMR type of Slurry Pump to be your reliable soltuion in acid conditions!

Metal Slurry Pump and Rubber Slurry Pump Materials List

Mineral Usage Pump

| Applications | ||

• Mining • Mineral processing • Construction • Chemical and Fertilization • Power generation • Pulp and paper • Oil and gas • Waste water treatment | • Ball mill discharge • Rod mill discharge • SAG mill discharge • Fine tailings • Flotation • Heavy media process • Minerals concentrate • Mineral sands • Coal-washing plant • Coarse sand • Coarse tailings • Dredging • FGD • Wet crushers Applications • Wet scrubber systems • Process chemical |

• Iron and Steel

• Ni acid slurry

• Fracking slurries

• Clay and sand slurries

• Kaolin clay

• Carbon slurry

• Lime mud

• Oil sands

• Phosphoric acid

• Phosphate matrix fertilization

• Pulp and paper

• Waste sludge

• Paper mill wastes and liquors

• Precipitated CaCO3

• Plaster

• Bottom/fly ash, lime grinding

• Dirty water

|

An Pump Machinery

As the slurry pump manufacturer of 50 years, we know exactly what you need in sump pump and we have the customized production schedule system.

It make we know every sump pump we sold and do the right production schedule to make you there is enough spare parts in stocking ready to shipment at any time.

New Spare Parts only need 3 days to retest, painting and package then ready to shipment at any time!

New Slurry Pump only need 7 days when therer is urgently required!

Click to know more...

An Pump Machinery, Your best Slurr Pump Manufacturer

Contact Us

| Roger Chen International Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:roger@angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 Call:0086-150-3285-7866 Call/whatsapp/Wechat: +86 137 805 12387 Skype:chenroger1215 |

No comments:

Post a Comment

Contact me at

roger@angroupcn.com

skype chenroger1215

Whatapp +86 137 805 12387